The Research and Evidence Based Council at Temple University Hospital System – Main Campus holds monthly meetings where nursing research is discussed. Out of the December 2022 meeting came the idea of a research endeavor to increase confidence in intravenous needle insertions and to reduce infections in the hospital. Many nurses expressed anxiety over this process and agreed that a study focused on ways to increase confidence would be warranted. One of the council members, librarian Travis Nace (Ginsburg Health Sciences Library) proposed the research idea and the collaboration between nursing and the library. Having something 3D printed would not only be cost feasible but further connect the hospital and library in their growing relationship involving research.

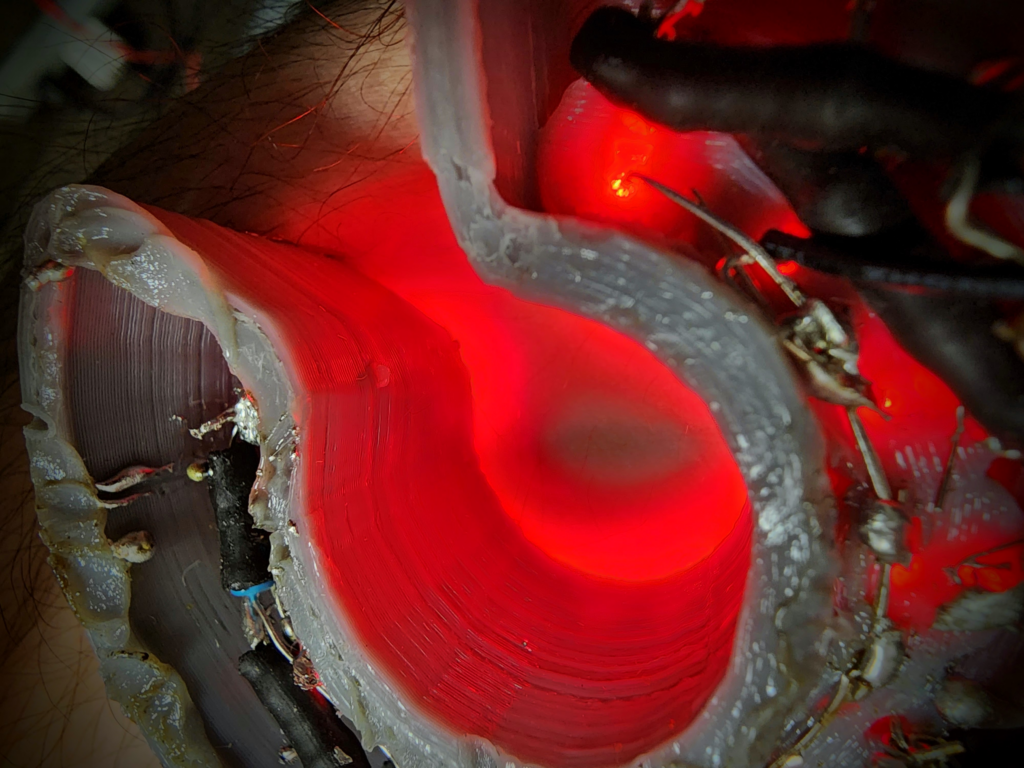

Innovation librarian Nick Perilli was brought on board to consult and utilize the Ginsburg Innovation Space’s technology to create a low-cost 3D-printed medical vein finder prototype. Red LEDs like the ones imaged above can shine through fat, muscle, and tissue with oxygenated blood, but they can’t shine through deoxygenated blood that runs through our veins. So, when pressed against the skin, veins show up as dark shadows surrounded by illuminated tissue, making it easier to insert needles.

Although there was precedent and even instructions for such a device that was 3D-printed in Europe, adopting the methods and obtaining the correct materials (wires, screws, LEDs, resistors, and more) from a supplier in North America proved to be a bit more challenging than anticipated. The 3D models also required some edits to improve the models’ strength and ease of assembly, which Perilli completed using Meshmixer and AutoCAD software. Once supplies were acquired and model edits were complete, Perilli and his Innovation Space team could print and assemble the prototype for the council with relative ease. This required basic electrical wiring and soldering; the device runs on two AA batteries and will have a switch to turn it off and on. This prototype model was printed using gray PLA filament with a Lulzbot Taz 6 PRO. Further iterations will be printed in ABS plastic, which is stronger, more heat resistant and easier to clean.

Moving forward, the Research and Evidence Based Council’s plan is to submit to the Temple University IRB to conduct a study using these 3D-printed vein finders. The study parameters and goals haven’t been finalized but this will be a tremendous partnership for both the Council and Temple University Libraries.