Lithium-ion batteries have been used extensively in past decades in a variety of applications from portable devices to airplanes and electric vehicles. Battery packages used in electric vehicles experience dynamic loadings, shocks, and large deformations during normal operation as well as in a crash scenario. It is of paramount importance to battery manufacturers and the automotive industry to better understand how cells deform under such loadings and what conditions might damage a cell and lead to failure.

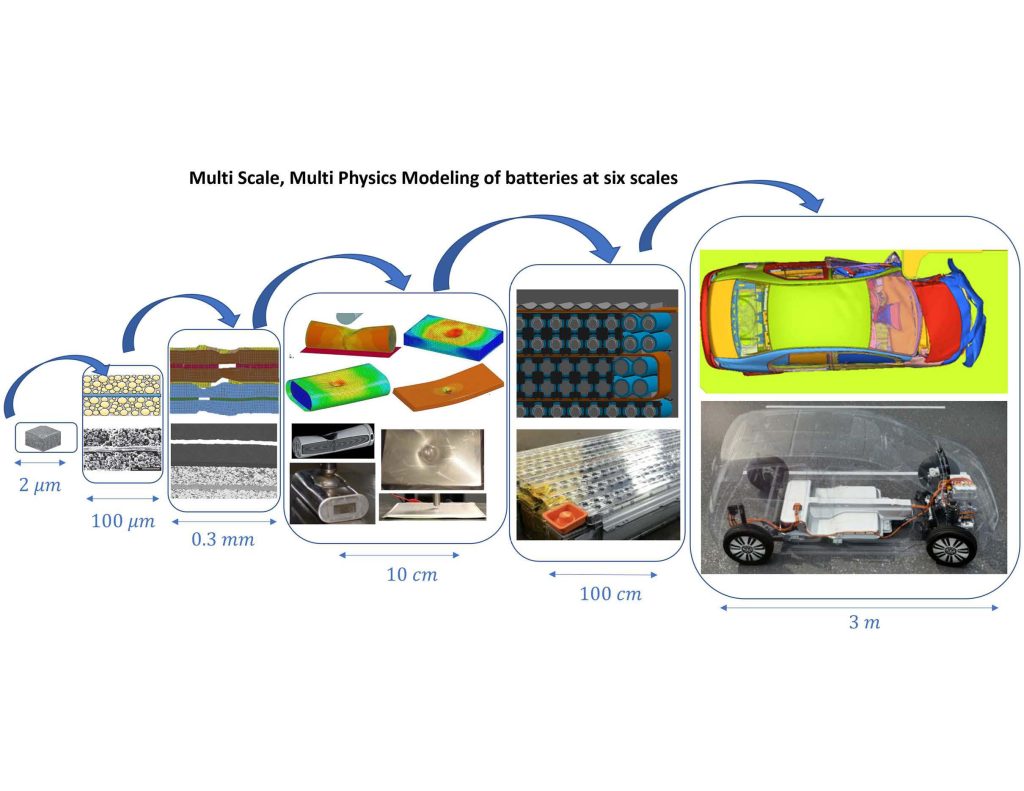

Research in Electric Vehicle Safety Laboratory (EVSL) is mainly focused on characterizing the mechanical behaviour of lithium-ion batteries, including cylindrical, pouch, and prismatic/elliptical cells. The mechanical properties of individual cell components (micro-level) as well as the entire cell (macro-level) are determined using various experimental methods and under various loading scenarios (uniaxial, biaxial, quasi-static, dynamic, etc.). Subsequently, finite element models are developed based on the obtained stress-strain relationships. The results of numerical simulations are used to predict the deformation and failure in the components, cells, modules and packs. These results are specifically useful in optimizing lithium-ion batteries and improving car safety.